Background

One of our customers came with us with a challenging project to reverse engineer and improve a part for a Subway system in the United States

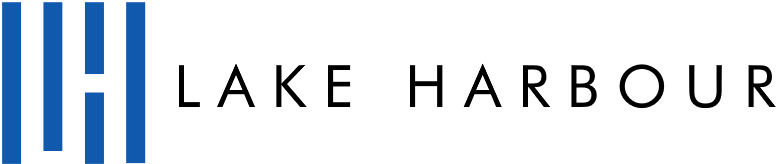

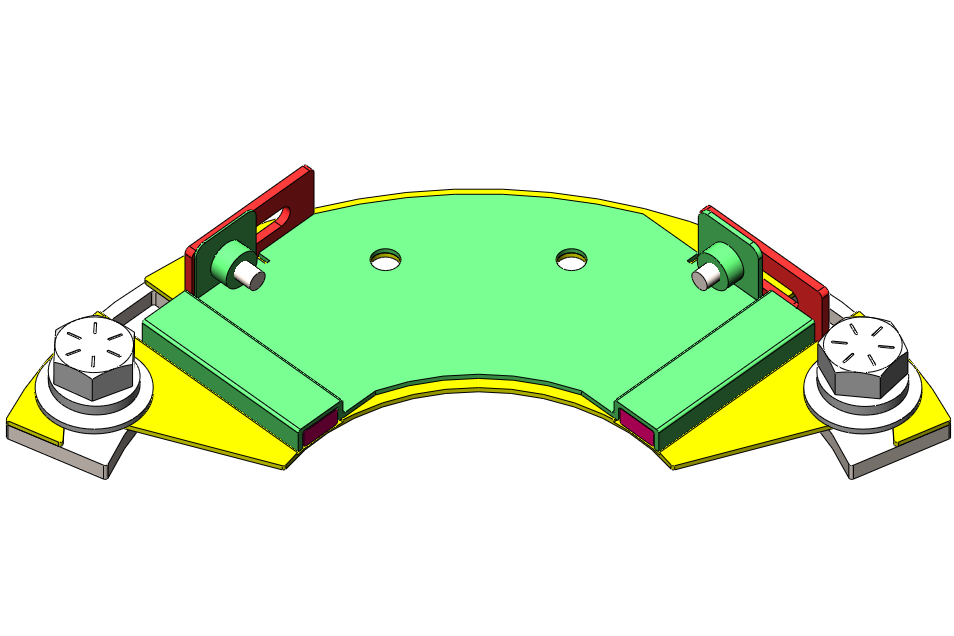

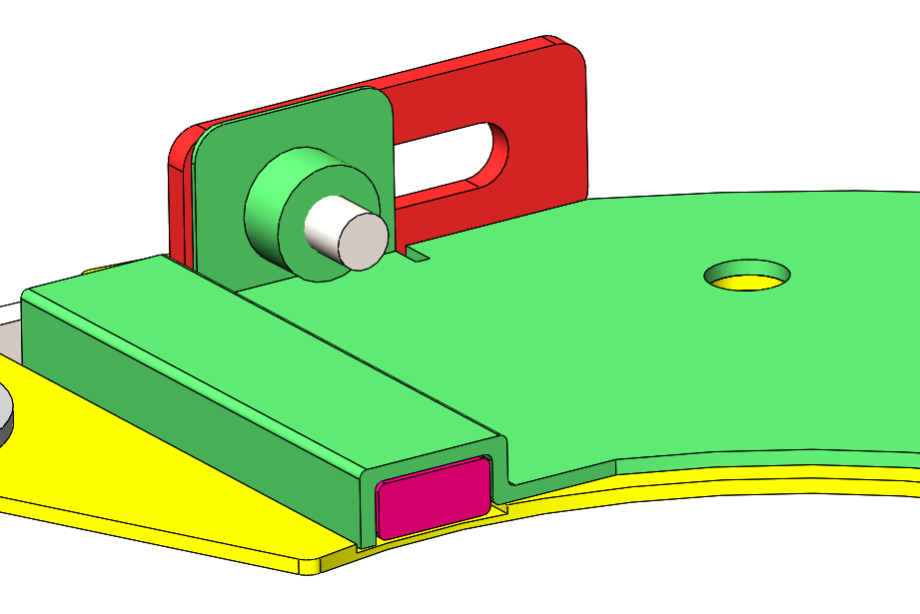

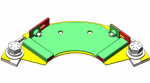

The part to modernize was an electrical gounding brush bracket. The objective was to increase the brush dimension while keeping the exterior vertical clearance constant as the space inside the subway did not allow for any increased size

Achievement

To succeed, Lake Harbour worked hand in hand with our supplier and our client to push the envelope to the limit of the manufacturing capabilities

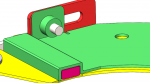

- 92% increase of the brush cross sectional dimension due to an innovative machining of a thin sheet of stainless steel to gain the required height and the expansion of the brush in the horizontal dimension

- Better welded surfaces with self aligning projection welds

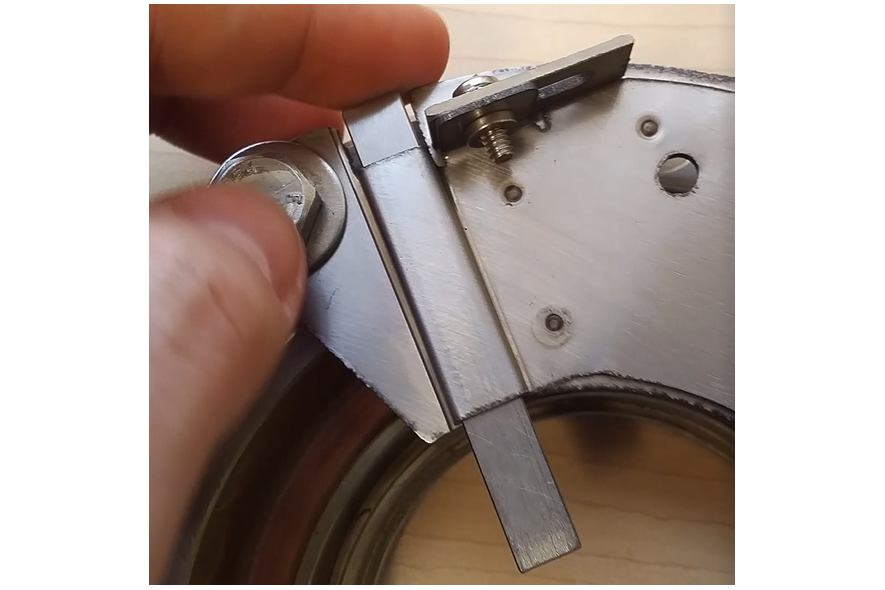

- Full compliance to the dimensional constraints validated by our quality control with our custom gauges manufactured for the project

- A manufacturable design the competitor said was impossible to make